ICO Asiapacific Indonesia provides a full range of Non-Destructive Testing services for oilfield tools, and manufacturer's equipment. Whether you require pre-inspection of bar stock prior to machining or analysis of a failed component, inspection can be tailored to meet customer requirements.

A non-destructive testing method that uses magnetic fields and fine magnetic particles to detect surface and near-surface flaws in ferromagnetic materials.

A non-destructive method that reveals surface-breaking defects by applying a penetrant liquid and developer to draw out and highlight discontinuities.

Careful observation and measurement to verify the physical condition, shape, and critical dimensions of components against specified standards.

Uses high-frequency sound waves to measure material thickness and detect internal flaws, ensuring structural integrity without causing damage.

Applying eddy currents or alternating magnetic fields to detect surface and near-surface defects, variations in material properties, or wall loss in conductive components.

A non-destructive testing technique that uses X-ray fluorescence or optical emission spectroscopy to verify the exact chemical composition of metal alloys.

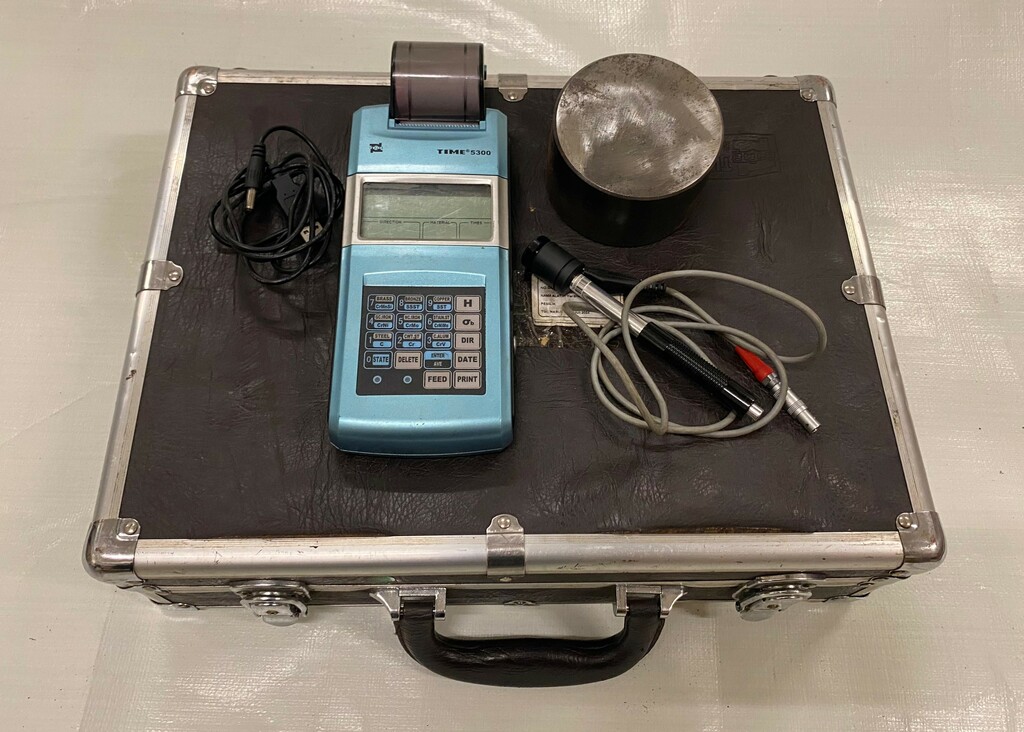

Measures a material’s resistance to deformation or penetration, helping assess strength, wear resistance, and material uniformity.

A non-destructive method that uses electromagnetic induction to detect surface and near-surface flaws, measure coating thickness, and assess conductivity in conductive materials.

Systematically investigates tool or equipment failures to identify underlying causes—whether from operational issues, material defects, or previous inspection processes—helping prevent recurrence and improve reliability.